Our STERIPLUS™ systems are equipped with a technology that combines shredding and decontamination of waste by sterilisation. A unique, fully integrated process, ideal for decontaminating your waste in complete safety for staff and environment.

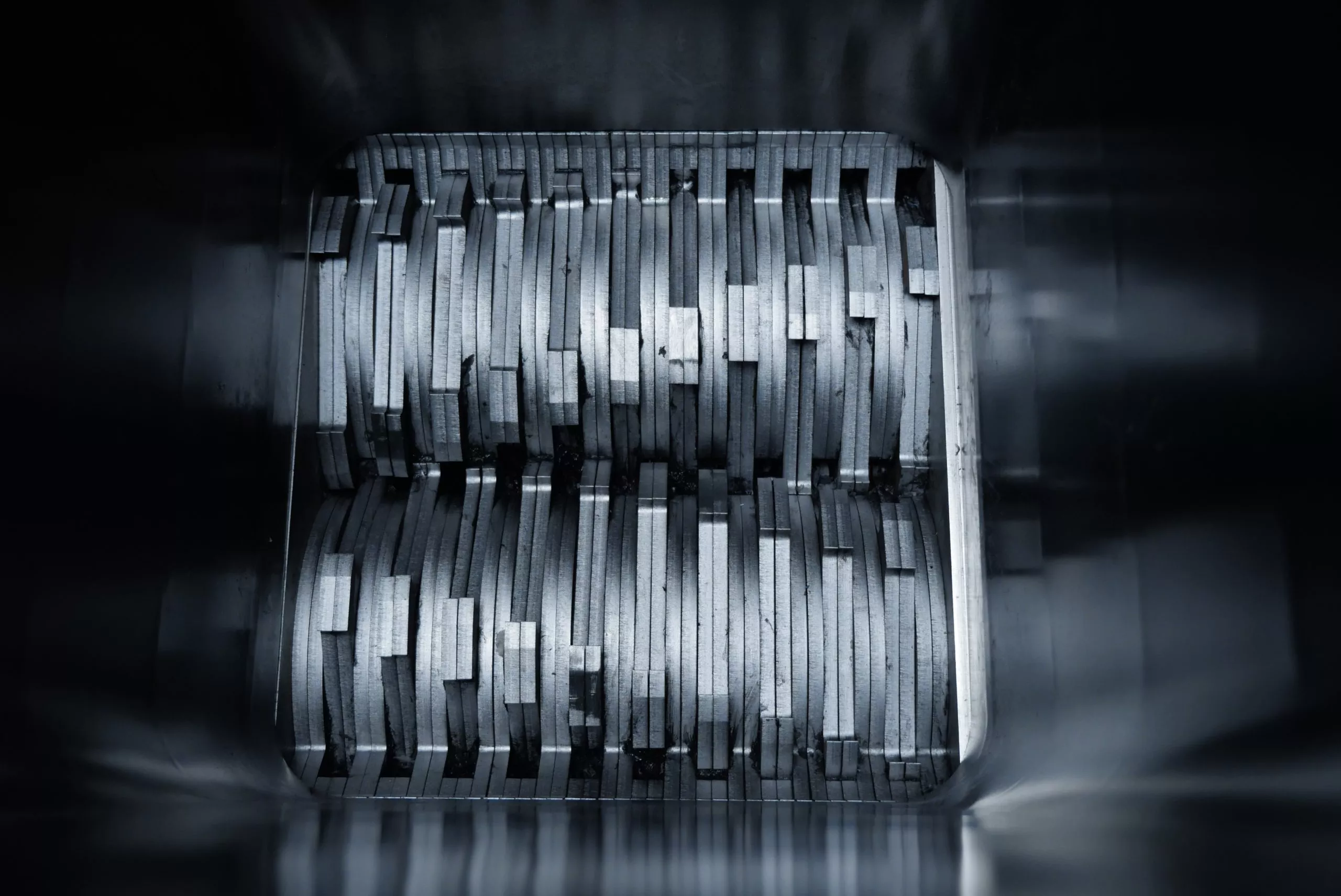

The shredder TESASHRED™ was specially designed by Tesalys to treat biomedical waste. Robust and efficient, it transforms your waste into unrecognizable 8-10 mm pieces.

The shredder blades/knives move forward and backward at low speed. If a blockage occurs, the shredder automatically starts again in the opposite direction.

The waste is pushed towards the shredder by a plate that automatically goes down. The system is able to detect the level of waste in the shredding chamber to ensure that all waste has been properly shredded.

The shredded waste falls by gravity into the decontamination chamber. Liquids also flow by gravity into a specific receptacle at the bottom of the decontamination chamber, where they will be treated before being discharged.

Shredding with the TESASHRED™ system turns waste into unrecognizable material as well as eliminating the mechanical risk.

The decontamination process consists of a conventional autoclave/sterilization cycle with the following steps: