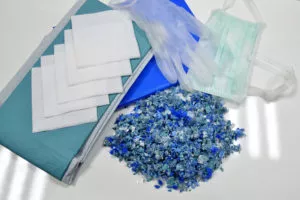

Most medical waste treatment systems today rely on an integrated shredding function to optimize the efficiency and safety of the process. But what is the real purpose of this key step, and what are the most effective technologies on the market?

Firstly, it is important to make a distinction between the most advanced “integrated” medical waste treatment systems (which have a dual function of shredding and decontaminating medical waste in the same equipment) and systems that do not perform shredding (or do so in separate equipment). Regulatory and normative developments tend to require the shredding and decontamination of medical waste to be carried out within the same machine, as the risks of incomplete treatment and spread of contamination are very high if operators have to transfer the medical waste between the decontamination system and the shredding system. In some countries, such as France, it is mandatory to perform shredding and disinfection operations in the same machine.

The shredding of medical waste serves several purposes :

The first is to reduce the volume of waste processed, as bags, cartons, and boxes are shredded and the waste is naturally “compacted.” Volume reduction can be as high as 80%, improving the environmental impact by significantly reducing the CO2 generated during transport for incineration/final storage of processed medical waste.

Secondly, shredding medical waste reduces psychological and emotional risk: by altering the visual appearance of the waste, it makes it unrecognizable as medical waste. This transformation helps to limit the potentially negative psychological impact on treatment line operators and the general public, even when the waste has been thoroughly decontaminated.

Shredding also reduces the “mechanical” risk of injury from sharp/cutting/piercing objects such as needles, scalpels, glass, etc. used in the medical field by cutting/crushing these objects.

Finally, shredding homogenizes medical waste and facilitates the decontamination process. For example, in steam sterilization systems, it facilitates the penetration of steam into the medical waste to eliminate any microbiological contamination.

For all these reasons, it is now recommended that medical waste treatment systems shred waste as finely as possible. The NFX 30 503-1 standard requires a particle size (size of pieces after shredding and decontamination) of less than 30 mm.

Shredding technologies: what are the differences?

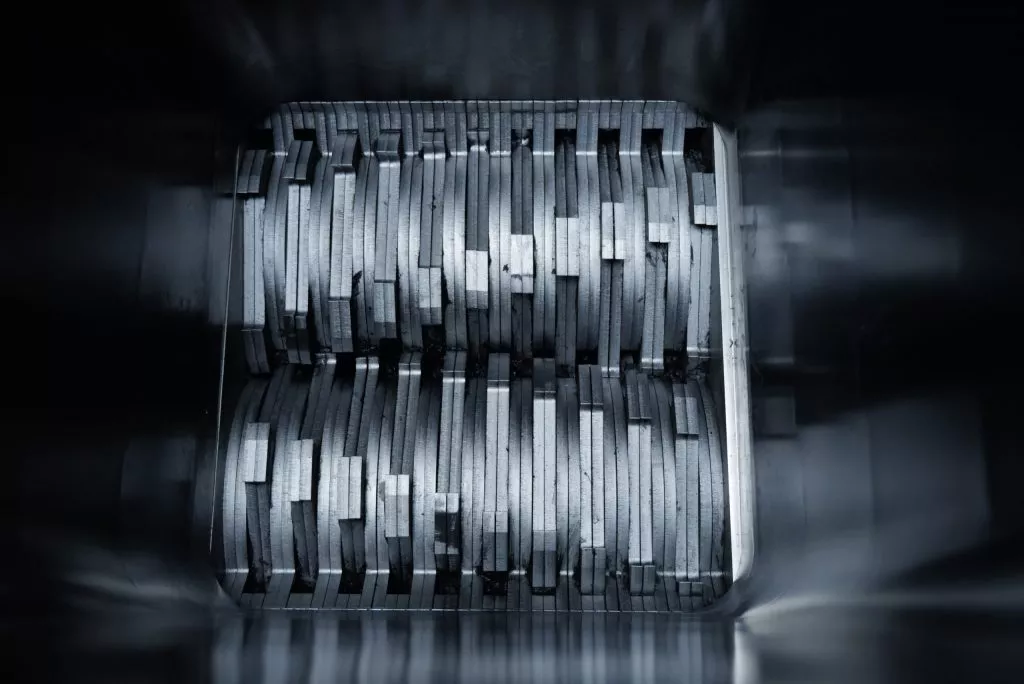

In integrated shredding and decontamination systems, there are essentially two shredding technologies: the 2- or 4-axis shredder with rotating knives and rotary blade shredding.

- Rotary blade shredding works like a blender, with the cutting blade at the bottom of the tank rotating at high speed to shred the waste. The advantages of this system are the simplicity of the mechanism and its maintenance (replacement of the blade, which must be changed regularly). Among the disadvantages, this system may encounter difficulties in shredding objects if there is a difference in weight and/or density (they may rotate in the tank without being caught by the blade) and can be noisy given the speed of rotation during shredding.

- Two- or four-axis shredding, equipped with rotating blades, works on the same principle as a document shredder or garden shredder. The knives and counter-knives, mounted in series, rotate slowly to drive and shred the waste simultaneously. The slower the rotation speed, the greater the torque exerted, ensuring optimal efficiency even on the most resistant materials. This more complex technology requires regular maintenance (lubrication, leak checks, etc.), but it offers many advantages. It can efficiently process all types of waste: plastics, metals, glass, non-woven textiles, liquids, etc. It also ensures that all waste introduced is completely processed, without the risk of blockages. The size of the knives can be adjusted to modulate the particle size of the waste, which is an advantage for certain specific applications. Another notable advantage is that the low speed operation makes this system particularly quiet. In addition, the process takes place in two stages: the waste is first introduced into a loading chamber, before being shredded and transferred to the decontamination chamber. In the event of a sorting error (e.g., introduction of non-shreddable objects), these items remain confined in the loading chamber. They can then be safely extracted after being decontaminated with steam.

The STERIPLUS™ and STERISHRED® ranges of shredders/sterilizers are equipped with patented TESASHRED™ technology based on the principle of a 2-axis shredder with rotating blades. The blades are made of extra-hard steel (Hardox®), ensuring high shredding efficiency and increased durability (blades guaranteed for 10 years). Shredding efficiency has been tested by an independent laboratory in accordance with standard NFX 30 503-1, achieving a particle size of between 10 and 15 mm for shredded waste. The system is extremely quiet, efficient and promotes volume reduction, reduced mechanical risk of injury from sharp/cutting/bladed objects, and steam penetration for optimal decontamination of infectious waste.

Focus: Treatment of sharp/cutting/piercing objects in shredders

The treatment of sharp/cutting/piercing objects in shredders deserves special analysis; this type of infectious medical waste presents additional risks due to the “psycho-emotional” risk (appearance of sharp/cutting/piercing objects after treatment) and the “mechanical” risk (risk of injury). For this type of medical waste, the quality of shredding is imperative. If sharp objects are not sufficiently processed during the treatment cycle in the shredder, this may trigger reluctance on the part of the staff responsible for handling medical waste after treatment.

For this reason, standard NFX 30-503-1 requires specific tests to assess the effectiveness of sharps shredding. These tests must be carried out on mixed loads composed of 70% sharps boxes and 30% soft medical waste, then reversed (30% sharps boxes and 70% soft medical waste). To be compliant, the results must show that at least 90% of the samples taken are less than 30 mm in size.

The requirement is not 100%, which means that some visually recognizable elements may remain after treatment, even though they are completely decontaminated. This requirement aims to ensure a sufficient reduction in the size of residues in order to limit risks to users and operators during post-treatment stages.

To improve staff safety and the quality of sharps shredding, here are some specific tips for this type of medical waste:

- Sharps must always be collected and processed in approved containers (rigid plastic containers or rigid cardboard boxes such as “safety boxes”). Never empty them directly into shredders.

- It is better to make “mixed” loads with soft medical waste and sharps to facilitate their shredding. Loads composed only of sharps can be more difficult to shred, and their appearance after treatment makes them more “recognizable.” .”

- It is advisable to wear protective gloves when unloading treated medical waste (whether sharps or not) to limit the risk of injury (burns/perforations/cuts).

As discussed in the article, not all shredding technologies are equally effective at shredding sharps. Tesalys’ TESASHRED™ technology has been tested in accordance with the standard and achieves a result of 92% of sharps loads with less than 3 cm (the particle size is closer to 1/1.5 cm). Compliance with these tests means that the shredders/sterilizers in the STERIPLUS™ and STERISHRED® ranges have a controlled shredding quality that allows sharps to be processed safely (the particle size is around 1/1.5 cm for 90% of the medical waste treated), which can then be treated as household waste without any additional treatment or precautions.

To sum up, choosing to use integrated shredding in infectious waste treatment systems means choosing to improve staff safety, optimize waste decontamination for all types of waste, and effectively meet regulatory requirements.

The shredding of your healthcare waste no longer holds any secrets for you!